Quartz Glass: Properties and Machining Challenges | Hard Yet Brittle?

Properties and Challenges of Quartz Glass

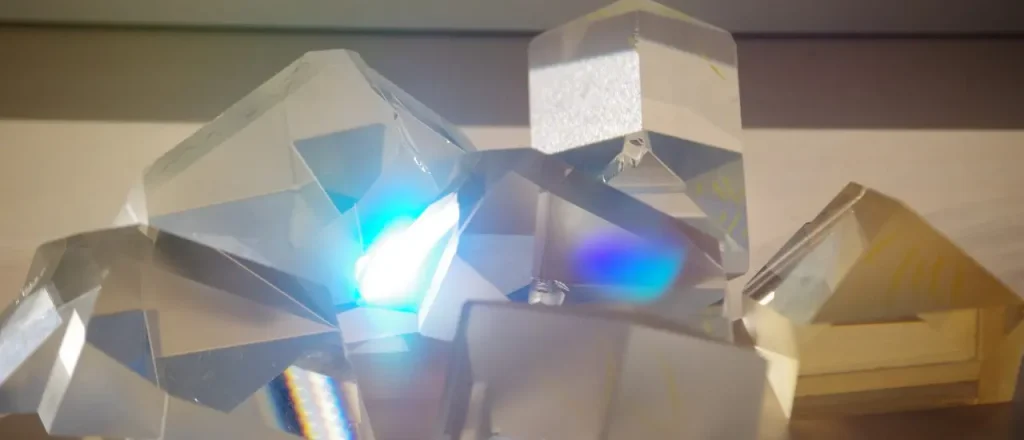

Quartz glass, as its name suggests, is a specialized type of glass primarily composed of quartz (silicon dioxide). It is manufactured by removing impurities to an extreme degree, resulting in very high transparency and excellent optical properties. This glass, made from quartz, has exceptional thermal and chemical resistance, playing a crucial role in various industries.

Properties of Quartz Glass

High Transmittance

Quartz glass is made from high-purity silicon dioxide, enabling it to transmit not only visible light but also infrared and ultraviolet radiation. This exceptional optical transmission makes it a valuable material for applications such as optical filters, optical fibers, and other advanced optical components.

Thermal Resistance

Quartz glass is highly resistant to thermal deformation and features a high softening point, allowing it to perform reliably in high-temperature environments. Its low thermal expansion coefficient also reduces the risk of cracking when exposed to rapid temperature changes.

This level of thermal stability makes quartz glass especially suitable for high-temperature experiments, semiconductor manufacturing processes, and other applications where precise thermal control is required.

Chemical Resistance

Quartz glass exhibits excellent chemical stability and strong resistance to a wide range of chemicals. However, like other types of glass, it is relatively vulnerable to alkaline substances.

This high level of chemical resistance is a key reason quartz glass is widely used in chemical experiments and laboratory environments where material reliability is essential.

Applications of Quartz Glass

Quartz glass is used in a variety of applications due to its unique properties:

Optical Filters

In optical filters, quartz glass selectively transmits specific wavelengths of light. This selectivity is crucial for precise measurements in scientific research and diagnostic equipment in medical technology. For example, filters can be customized to block ultraviolet light while allowing visible light to pass through.

Laboratory Chemical Equipment

Quartz glass offers excellent thermal and chemical resistance, ensuring reliable performance even under harsh experimental conditions. In experiments involving high temperatures or strong acids and bases, containers and tools must endure these stresses without degrading. Quartz glass equipment maintains its integrity, helping to ensure consistent and accurate experimental results.

Semiconductor Components

As components in semiconductor devices, the high-temperature stability and chemical resistance of quartz glass support the precision and efficiency of manufacturing processes. In semiconductor chip manufacturing, extremely fine structures must be formed accurately, and components must be protected from chemical substances and high temperatures. Quartz glass components maintain their performance under these harsh conditions, improving both precision and efficiency in semiconductor manufacturing.

Optical Fibers

In optical fibers, the high transmittance and low light loss of quartz glass are crucial. These properties enable efficient and high-speed data communication, which is essential for internet and communication networks. By transmitting data as light signals over long distances, signal degradation can be minimized.

Challenges in Processing Quartz Glass

Brittleness

The brittleness of quartz glass makes it difficult to process. Although it is very hard, this also makes it prone to cracking. Especially during precise cutting or drilling, fine cracks can occur, leading to damage.

High Precision Requirements

The processing of quartz glass often requires extreme precision. In applications involving optical instruments like lenses or prisms, even minor errors in processing can significantly affect optical performance. Therefore, advanced technology and highly precise machinery are necessary, which can increase processing costs.

Loss of Transparency at High Temperatures

The loss of transparency at high temperatures can limit its use in certain applications. When quartz glass is exposed to high temperatures, its transparency decreases, affecting its optical properties. This issue is particularly significant in optical measurements under high-temperature conditions or in processes that require visual monitoring under intense heat.

Difficulty in Achieving Smooth Finishing

Achieving a smooth finish when processing quartz glass is challenging. Due to its brittleness, even with conventional glass processing techniques, fine scratches can easily remain on the surface, negatively affecting quality and strength. Special processing techniques or post-processing are often necessary, adding to the cost and processing time.

Trust Koyo High Precision for Quartz Glass Machining

At Koyo High Precision, we combine advanced machining technology with years of practical experience to handle the precision machining of quartz glass and other difficult-to-cut materials.

Quartz glass requires strict control due to its brittleness and sensitivity to machining conditions. We optimize every process by closely monitoring chip behavior, tool wear, surface quality, and machining stability to achieve accurate and reliable results.

We provide customized machining solutions tailored to your specific requirements, from prototypes to precision components. Contact Koyo High Precision for consultations or quotations. We are ready to support your quartz glass machining needs.