Introduction to Micro-Hole Machining and Its Applications

Micro-hole machining is a precision technology used to create holes with diameters of 1 mm or smaller. This highly specialized process is critical for producing medical devices, electronic components, and precision mechanical parts where accuracy and reliability are essential.

What is Micro-Hole Machining?

Micro-hole machining refers to the process of creating extremely small, highly accurate holes. This technology plays a vital role in various industries, including medical devices, electronics, and precision machinery.

Common Methods of Micro-Hole Machining

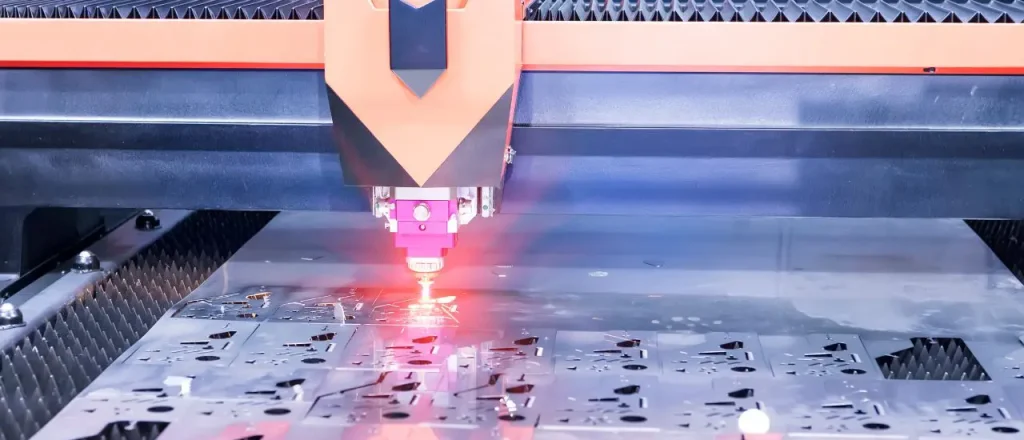

Laser Machining

Laser machining uses a concentrated laser beam to achieve precise machining, making it ideal for hard materials and complex shapes. The excellent directionality and focus of laser light allow for high-energy concentration in a narrow area, enabling fine-detail processing. However, laser machining can sometimes result in tapered hole edges and surface charring. Adjusting machining parameters and using post-processing techniques are crucial to minimizing these effects.

Electrical Discharge Machining (EDM)

EDM uses a thin wire electrode to remove metal using electrical discharges, enabling high-precision machining for all conductive materials, including high-hardness metals. However, since EDM requires electrical conductivity, it is not suitable for non-metallic materials or those with low conductivity. While EDM provides precise results, it is relatively slow, making it best suited for applications demanding exceptional precision, such as medical devices and aerospace components.

Cutting Machining

Cutting machining involves using specialized cutting tools to remove material and form products with high accuracy. This method is versatile, capable of handling a wide range of materials while maintaining precision. By selecting the right tools and optimizing machining conditions, manufacturers can achieve precise shapes and tight dimensional tolerances. At Koyo High Precision, we specialize in cutting machining and have extensive experience in deep hole machining with an L/D ratio of 75 or higher.

Precision Measurement in Micro-Hole Machining

Accurate measurement is crucial for ensuring quality and precision in micro-hole machining. The use of appropriate measuring instruments plays a key role in maintaining product consistency.

Pin Gauge

A pin gauge is a precision measuring tool used to check the diameter and tolerance of small holes. It consists of cylindrical pins with accurately defined diameters that are inserted into the hole being measured. By observing how the pin fits, whether it goes in smoothly or with resistance, it is possible to assess the hole’s exact diameter and shape accuracy. Since it measures through direct contact, a pin gauge provides very high measurement precision.

Image Measurement Devices

This non-contact measurement method uses a camera to capture high-resolution images of the target object, analyzing dimensions through image processing technology. It enables instantaneous measurements within the field of view, making it ideal for precise dimensional analysis.

Applications of Micro-Hole Machining

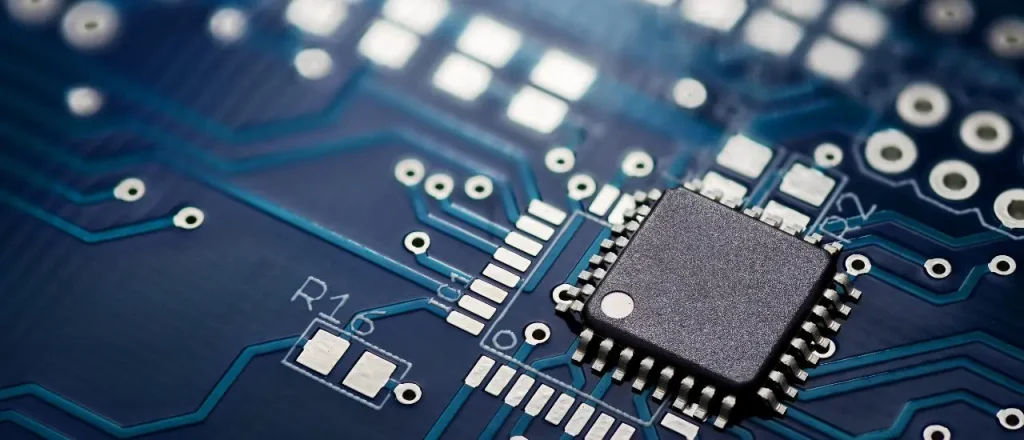

Micro-hole machining is widely utilized in the manufacturing of high-precision mechanical parts and components, particularly in the semiconductor and medical industries.

- Semiconductor Industry: Micro-holes are essential for fine wiring and precise component placement in semiconductor manufacturing.

- Medical Devices: Ultra-small holes in syringes, endoscopes, and surgical instruments contribute to improved treatment effectiveness and patient comfort.

Trust Koyo High Precision for Machining Materials

At Koyo High Precision, we combine cutting-edge technology with years of hands-on experience to expertly handle the machining of even the most difficult-to-cut materials.

No matter how challenging the material, we can identify the perfect machining conditions by carefully monitoring chip formation, tool wear, cutting surface quality, and even the sounds during machining.

We are committed to providing customized solutions that meet your unique needs. Contact us today for consultations or quotations — we’re here to help with all your difficult-to-machine material requirements.