Machining Techniques and Tips: A Comprehensive Guide to Metal Cutting Processes

Metal Cutting Processes

Metal cutting processes play a critical role in precision parts manufacturing by enabling materials to be machined into accurate shapes and dimensions. These processes are widely used to produce components that require tight tolerances and consistent quality.

This article provides an overview of common metal cutting methods, including lathe machining, milling, and drilling operations. It also explains the advantages of Computer Numerical Control (CNC) technology in achieving high precision, as well as effective chip control techniques that support stable and efficient machining.

Metal cutting is a machining process in which excess material is removed from a workpiece to obtain the desired shape and size. Cutting tools are used to shear material from metals and other engineering materials, and the final machining accuracy and surface finish depend on factors such as tool geometry, tool material, cutting speed, and feed rate.

Metal Cutting Methods

There are several metal cutting methods, and the appropriate method must be selected based on the metal’s properties and the intended application.

Lathe Machining

Lathe machining is one of the fundamental machining techniques used in precision manufacturing. In this process, a cylindrical workpiece is rotated while a cutting tool removes material from its outer or inner surface.

This method enables high dimensional accuracy and excellent surface finish, making it ideal for producing round or rotational components such as shafts, bushings, and rings. Lathe machining is widely used across industries that require tight tolerances and consistent quality.

To achieve precise results, key parameters such as spindle speed, tool feed rate, and depth of cut are carefully controlled. Proper optimization of these conditions ensures stable cutting, accurate geometry, and reliable surface quality.

Milling

Milling is a widely used machining process in which a rotating cutting tool removes material from a stationary workpiece. This process is highly effective for creating a wide range of shapes, including flat surfaces, slots, pockets, grooves, and complex contours.

Because milling can handle intricate geometries and multi-axis movements, it is essential for manufacturing precision components used in industries such as automotive, aerospace, electronics, and medical devices. Components like housings, brackets, plates, and gear profiles are commonly produced using milling operations.

Milling also allows multiple machining operations such as face milling, end milling, and contour milling to be performed within a single setup. This improves machining accuracy, reduces setup time, and increases overall production efficiency, making it a key process in modern precision manufacturing.

Drilling

Drilling is the process of creating holes in materials using drill bits. This machining technique excels in its ability to create holes of different diameters and depths with high precision.

Hole-making is a critical step in most manufacturing processes, particularly when assembling components with bolts and rivets, where precise hole positioning and sizing are required.

Drilling is widely used for machining mechanical parts as well as producing small components like electronic circuit boards.

Advantages of Cutting Processes

High-Precision Machining

One of the key advantages of cutting processes is their ability to produce components with extremely high dimensional accuracy. When combined with Computer Numerical Control (CNC) technology, cutting operations can achieve precision at the micron level, ensuring consistent and reliable results.

High-precision machining is critical for industries that require strict tolerances, such as aerospace, medical devices, and semiconductor equipment. The capability to repeatedly manufacture identical parts under tightly controlled conditions improves product reliability, reduces variation, and strengthens overall quality control.

Complex Shape Machining

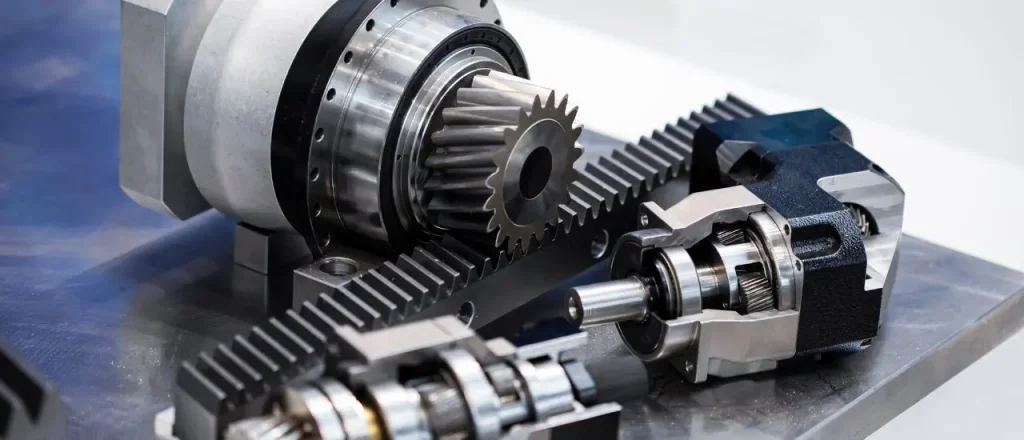

The flexibility of cutting processes is a significant advantage in precision manufacturing. By using machines such as lathes, milling machines, and CNC machining centers, manufacturers can produce components with complex three-dimensional shapes and fine details.

Cutting processes allow precision parts to be machined from a single solid block, minimizing the need for additional assembly steps. This approach improves dimensional accuracy, structural integrity, and overall consistency.

As a result, custom gears and mechanical components with special profiles can be manufactured efficiently while maintaining high precision and repeatability.

Minimal Material Deformation

In cutting processes, the force applied to the material is minimized, which helps prevent deformation during machining.

Maintaining the dimensional and shape accuracy of parts is extremely important, especially in precision manufacturing. Cutting processes can minimize internal stress in the workpiece, improving the quality and lifespan of the final product.

Disadvantages and Considerations of Cutting Processes

Time-Consuming Process

In cutting processes, material is removed layer by layer to create the desired shape. This can take considerable time, especially when a large volume of material needs to be removed or when working with complex geometries.

For instance, when producing small precision parts from a large metal block, the more material that is cut away as waste, the longer the process takes. As a result, for one-off or custom-made components, this time requirement can become a major drawback, particularly when overall project efficiency and turnaround time are critical.

Tool Wear

In cutting processes, tools rotating at high speeds are in direct contact with materials, which increase the risk of tool wear and damage.

If the tool material or cutting speed is not properly selected, tool wear can occur at a faster rate, affecting machining accuracy and production efficiency.

Key Points in Cutting Processes

Chip Management

Chips generated during cutting operations can directly impact machining accuracy and machine productivity.

That is why effective chip removal is critical for maintaining a clean cutting area and preventing excessive heat buildup. Proper chip management stabilizes cutting conditions, improves surface quality, and significantly extends tool life.

For example, high-pressure coolant systems enable rapid chip evacuation, supporting uninterrupted, high-precision machining.

Appropriate Tool Selection

Chips generated during cutting operations can significantly affect machining accuracy and overall productivity.

Effective chip removal is essential to maintain a clean work area and prevent heat buildup. Proper chip management not only stabilizes cutting conditions but also improves surface finish and prolongs tool life.

For example, high-pressure coolant systems quickly evacuate chips from the cutting zone, enabling smooth, continuous, and high-precision machining.

Trust Koyo High Precision for Machining Challenging Materials

Koyo High Precision brings extensive expertise and proven experience in precision machining. We are equipped to handle a wide range of materials, from pure tungsten to other difficult-to-machine alloys, delivering high-accuracy results every time.

Our machining services support diverse industries, including automotive, medical devices, and semiconductor equipment, providing solutions for even the most complex and demanding manufacturing challenges.

If you are looking for a reliable partner for precision machining, contact Koyo High Precision today to discuss your project or request a consultation.