Materials

Tungsten

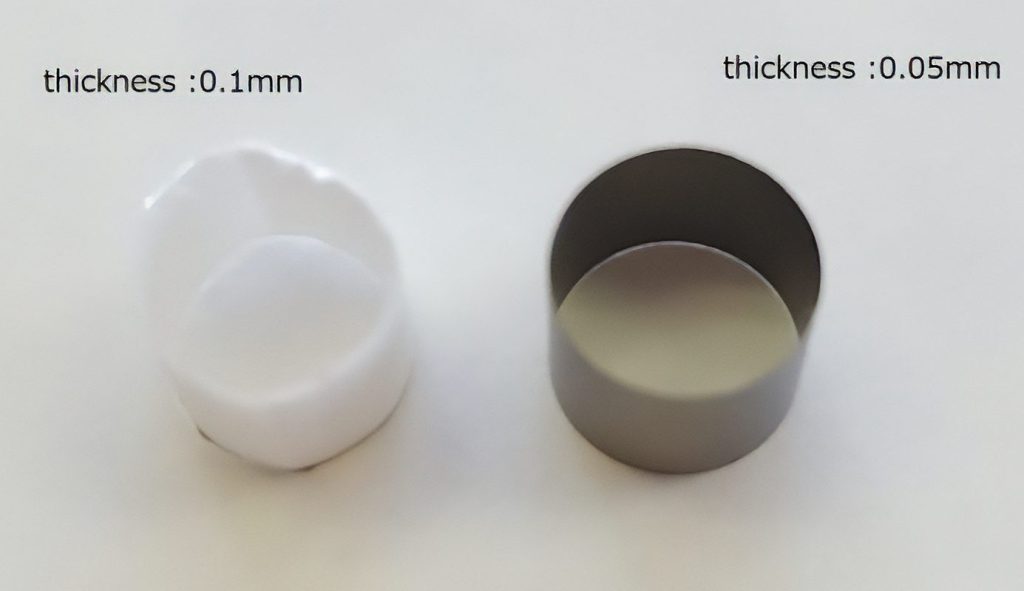

t0.05-Thin wall processing of tungsten

- Paper thickness is 0.1mm

- Product thickness is 0.05mm

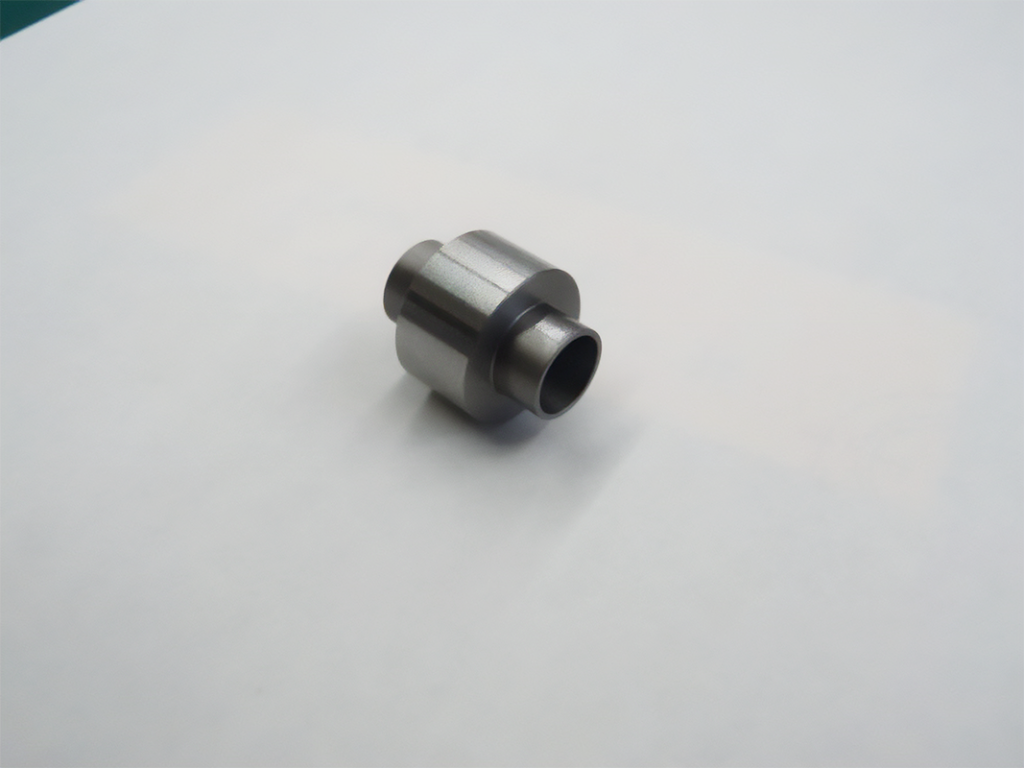

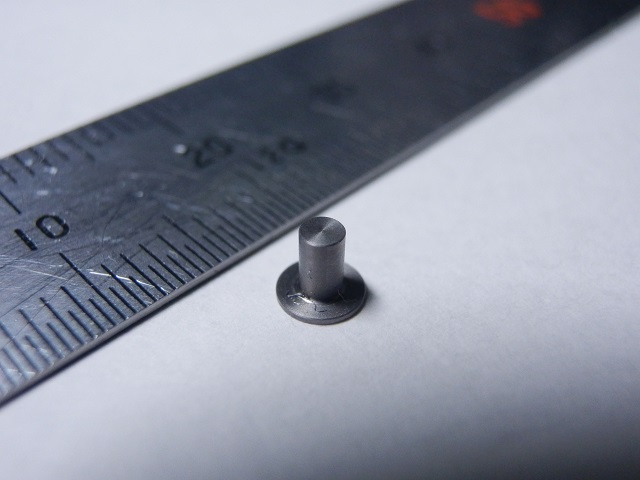

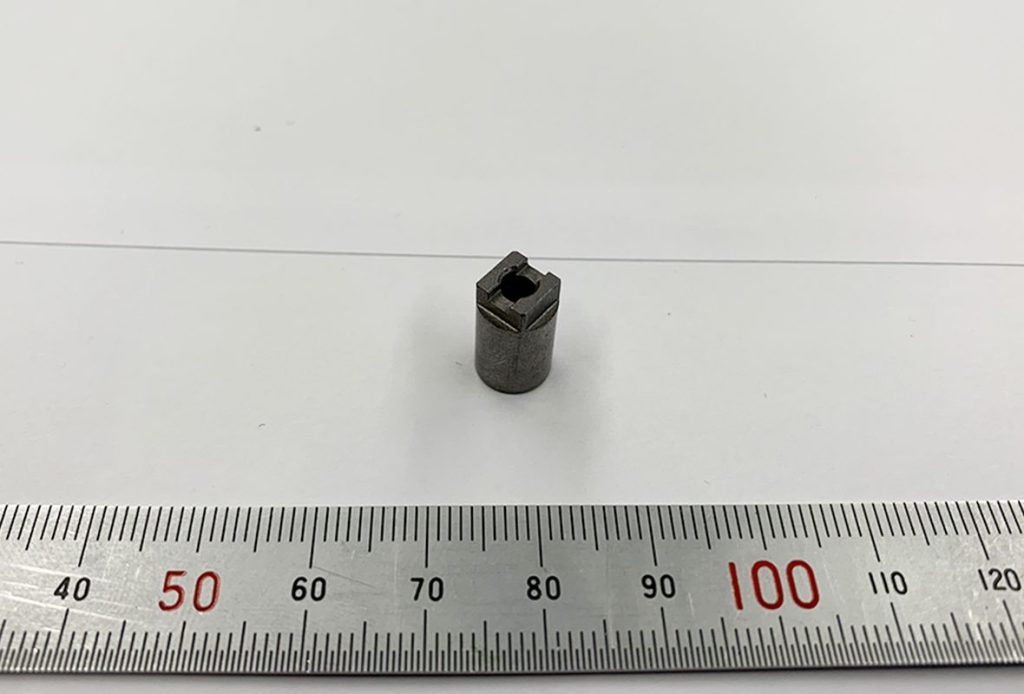

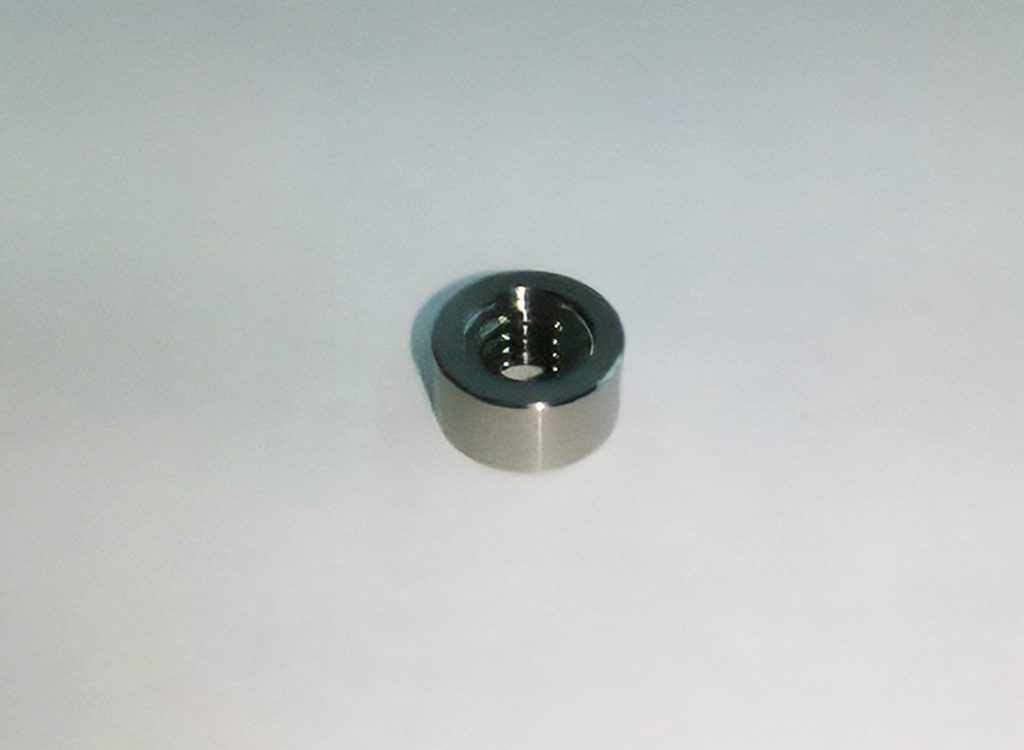

Pure Tungsten

- Inner diameter accuracy ±3microns. Surface roughness Ra0.5.

- Mass production processing. Thousands produced monthly.

- Outer diameter φ12× Inner diameter φ6. Not through.

- M3 tap on the other side.

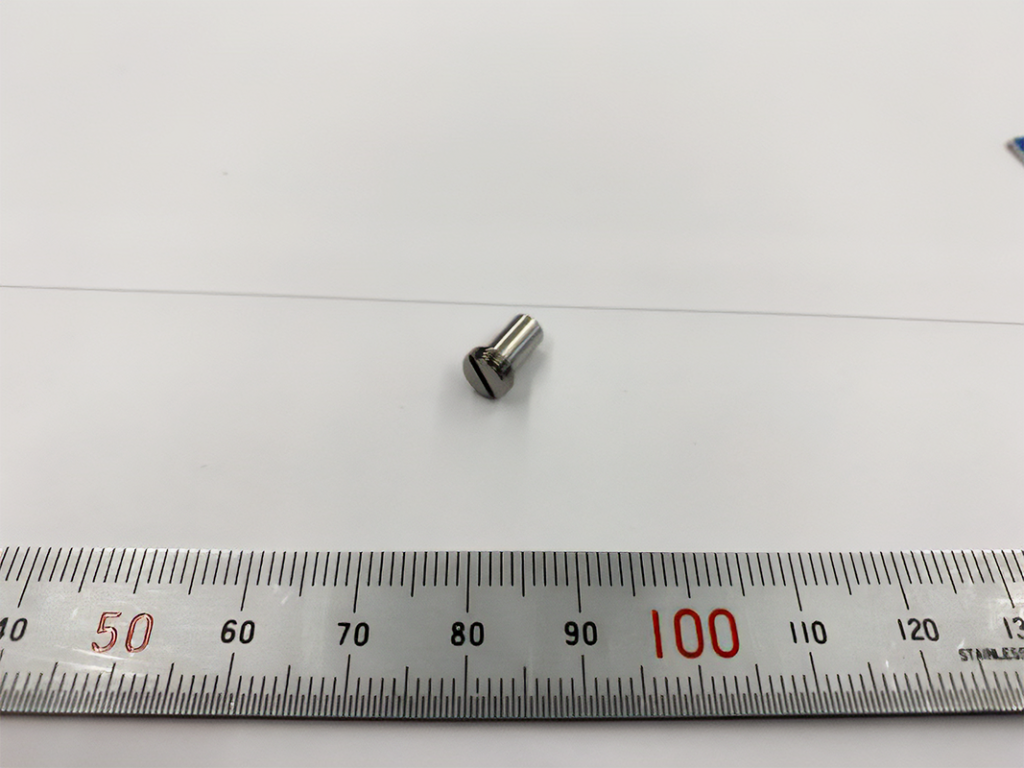

Pure Tungsten Screw

- Pure Tungsten Screw on Sale

- inch size available

- inspection by gauge

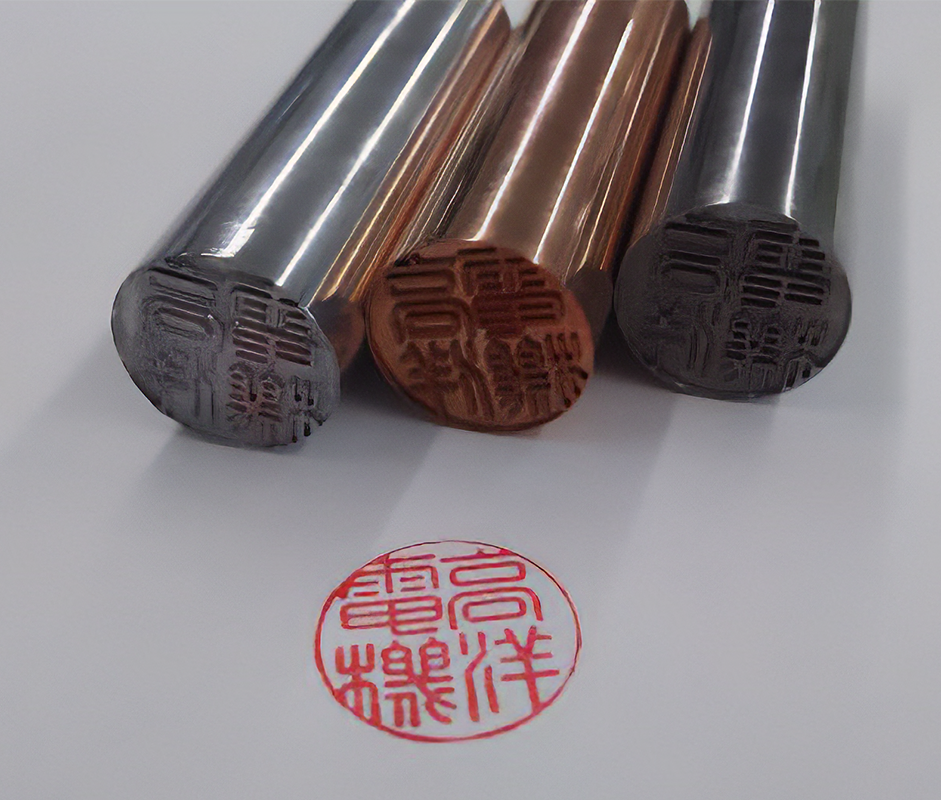

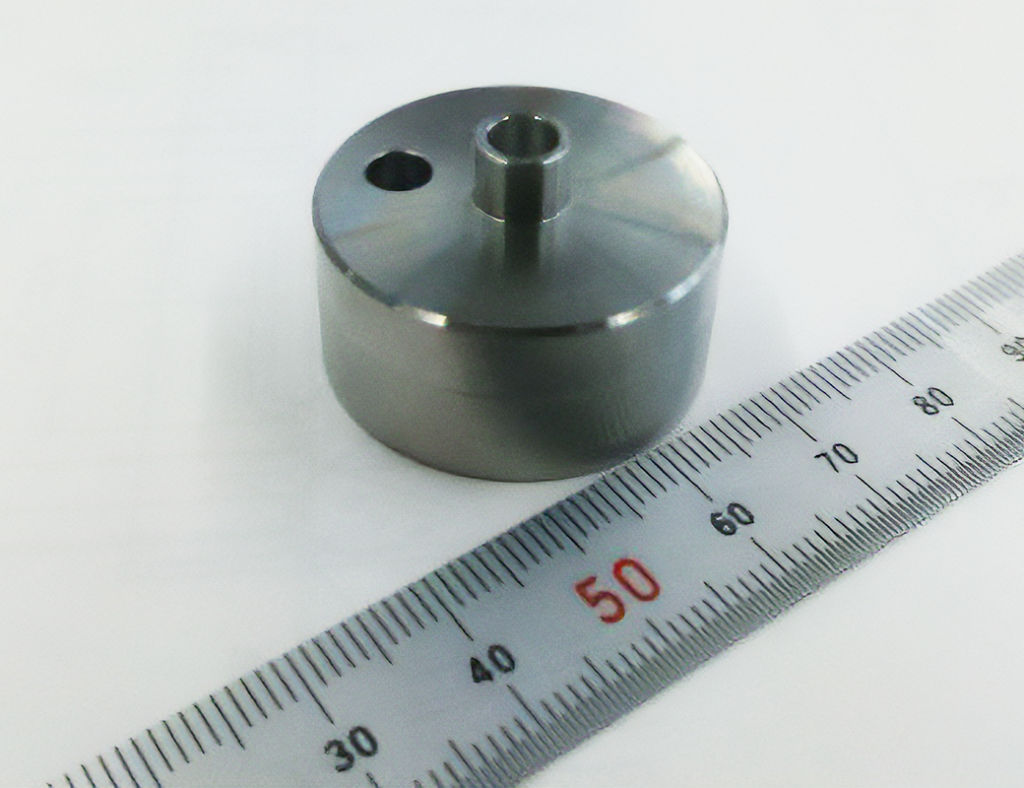

Tungsten Seal

- Official seal size stamp made with Tungsten

- Made with Aluminum and pure copper for weight comparison

Pure Tungsten Screw

- With hexagonal hole

Pure Tungsten

- M6

- Outer screw

Pure Tungsten

Outer screw

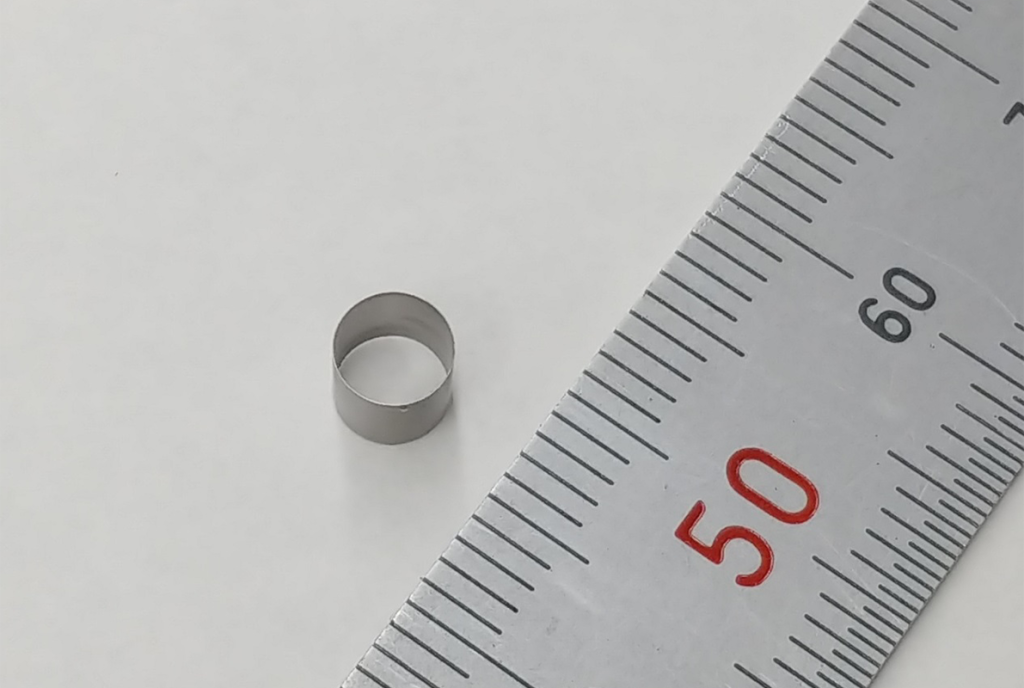

Pure Tungsten

- Processing from round bar.

- Wall thickness 0.2~0.8.

- Outer diameter φ4~8. Full length 10mm.

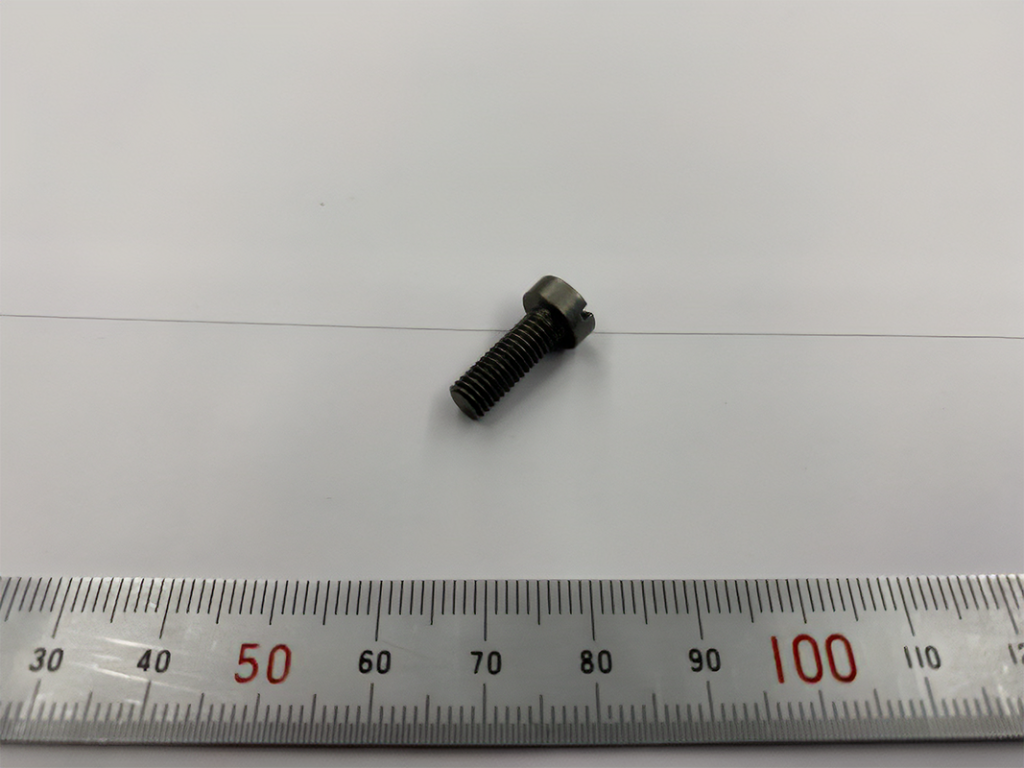

Tungsten

- M5x8(L)、M5x12(L)

- Screw with hexagon hole

Pure Tungsten

- Φ2×L3.5mm -Pin

Pure Tungsten

- Shaft

- Full length 300mm

- End face M5

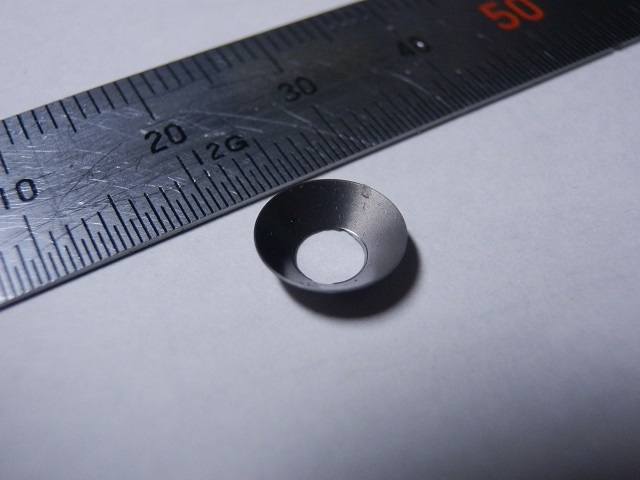

Pure Tungsten

- Wall thickness 0.2

- Outer diameter Φ8.5

- Inner diameter Φ4

- Full length 2.5mm

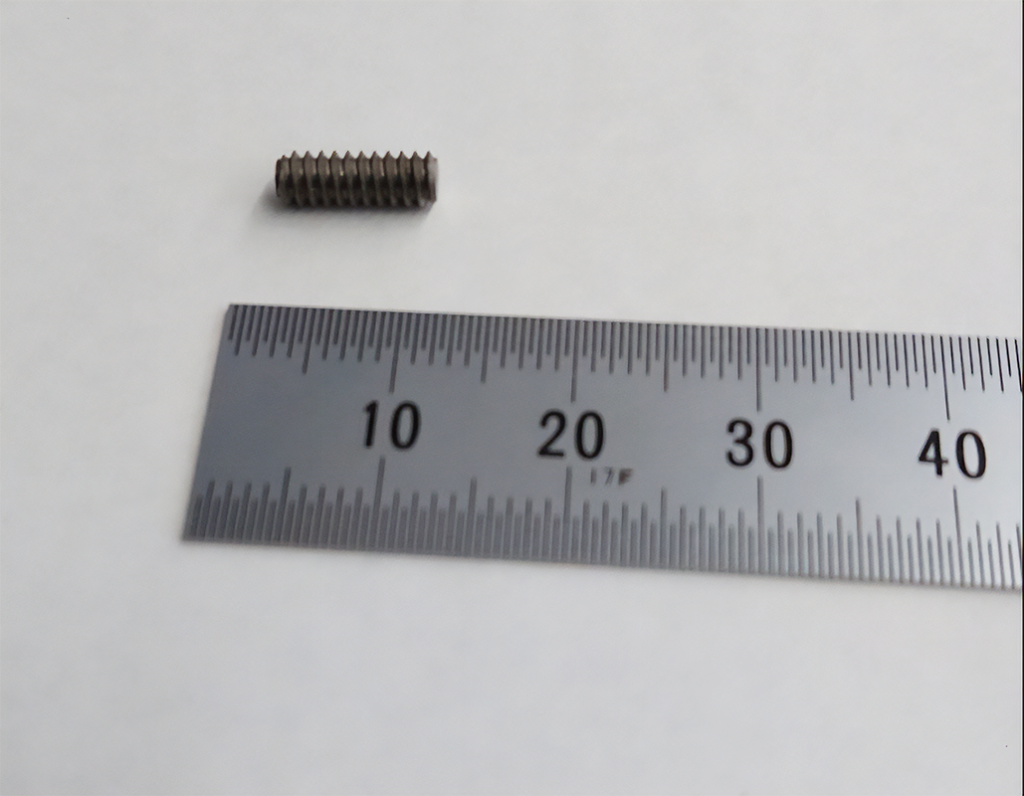

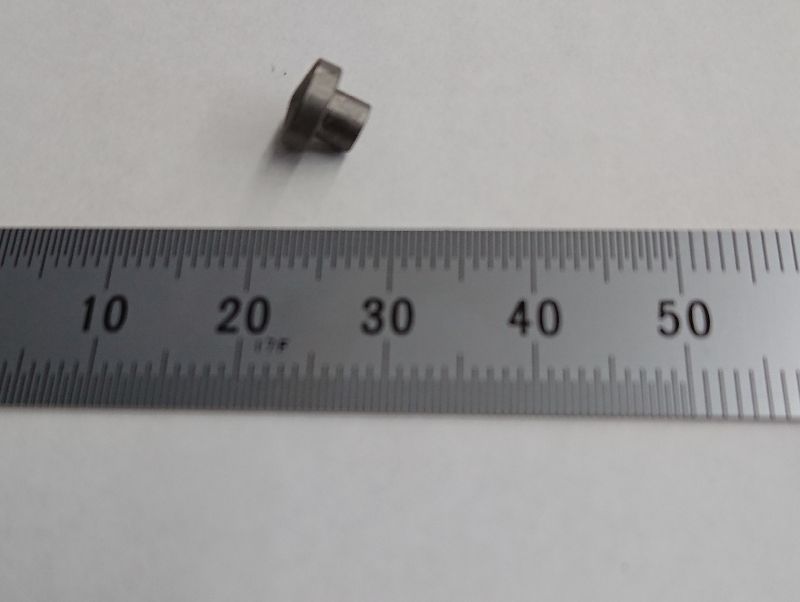

Pure Tungsten

- M3 -Set screw

Pure Tungsten

- Wall thickness 0.4

- Outer diameter Φ9

- Inner diameter Φ4

- Full length 2mm

Thin wall processing of tungsten

- Tungsten processed thinner than paper

Pure Tungsten

- Chopstick pillow

Pure Tungsten

- Product size is Φ4.3×4.2mm

- Product thickness is 0.05mm

Pure Tungsten Screw

- M4-Screw

Pure Tungste

- φ0.5, L24.5

Pure Tungsten

・Φ0.5,L24.5 through hole, C0.8, Ra0.7

Pure Tungsten

- Inner screw

Molybdenum

Pure Molybdenum Bolt

- Pure Mrbuden M5 Bolt

Pure Molybdenum

- Block

Pure Molybdenum

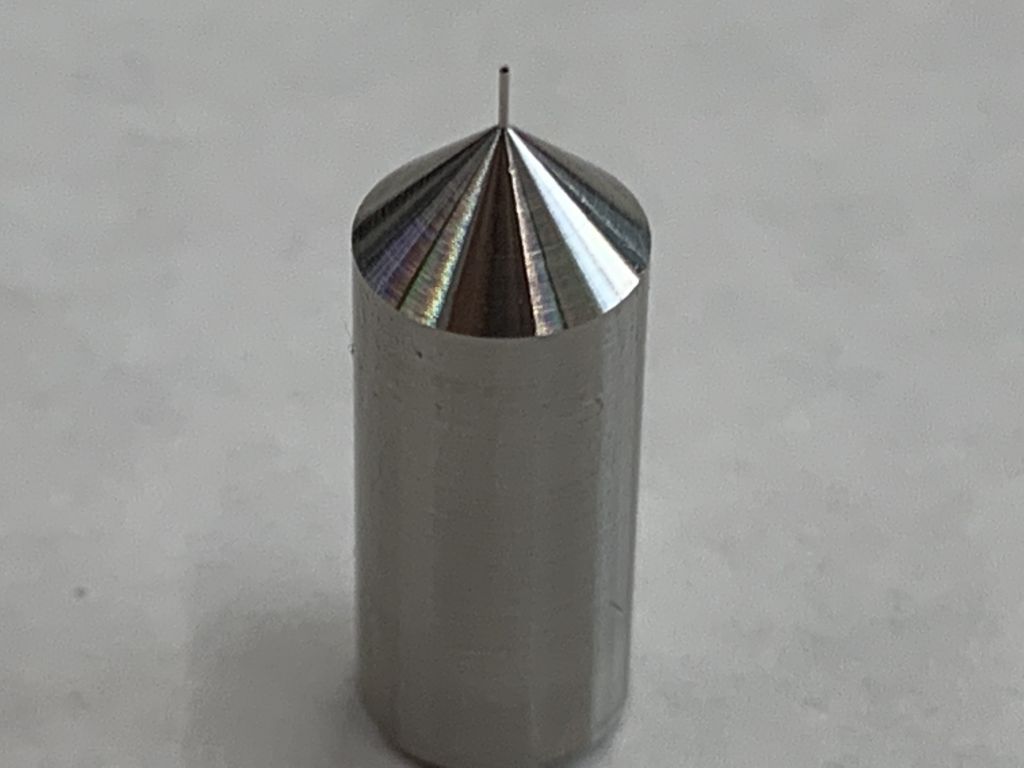

- Teper processing

Platinum

Platinum Microfabrication

- Nozzle shape

- Outer diameter 0.2mm, inner diameter 0.15mm, wall thickness 0.025mm

- Penetrating a 1mm hole from the other side

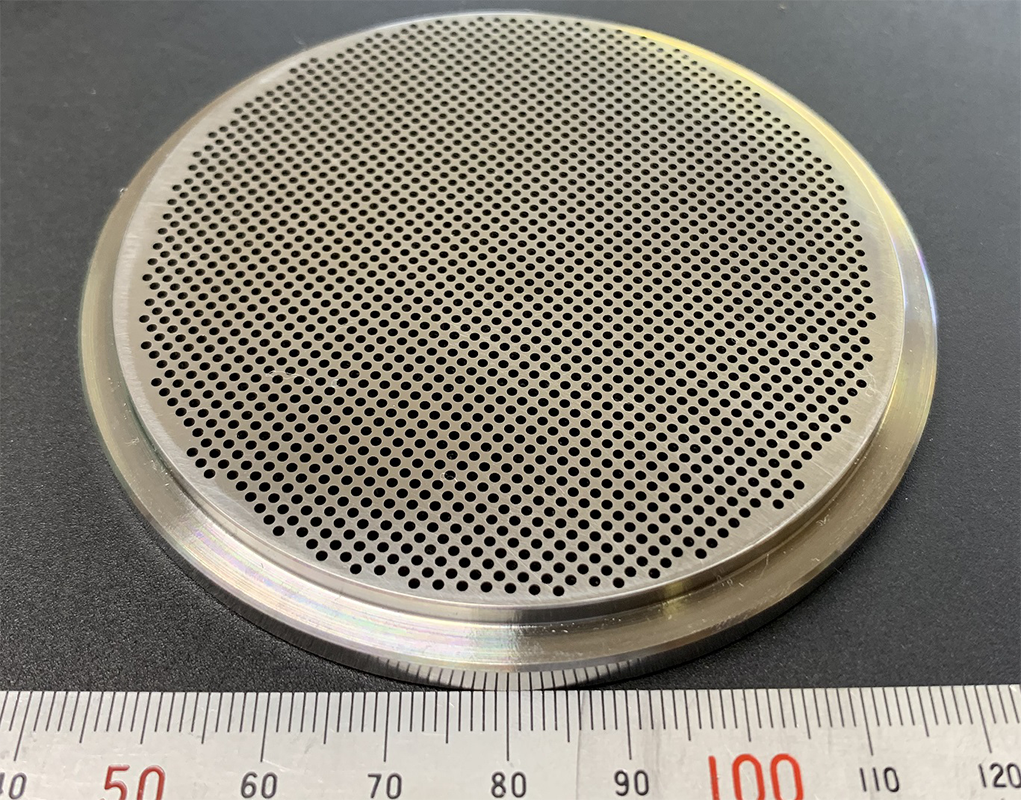

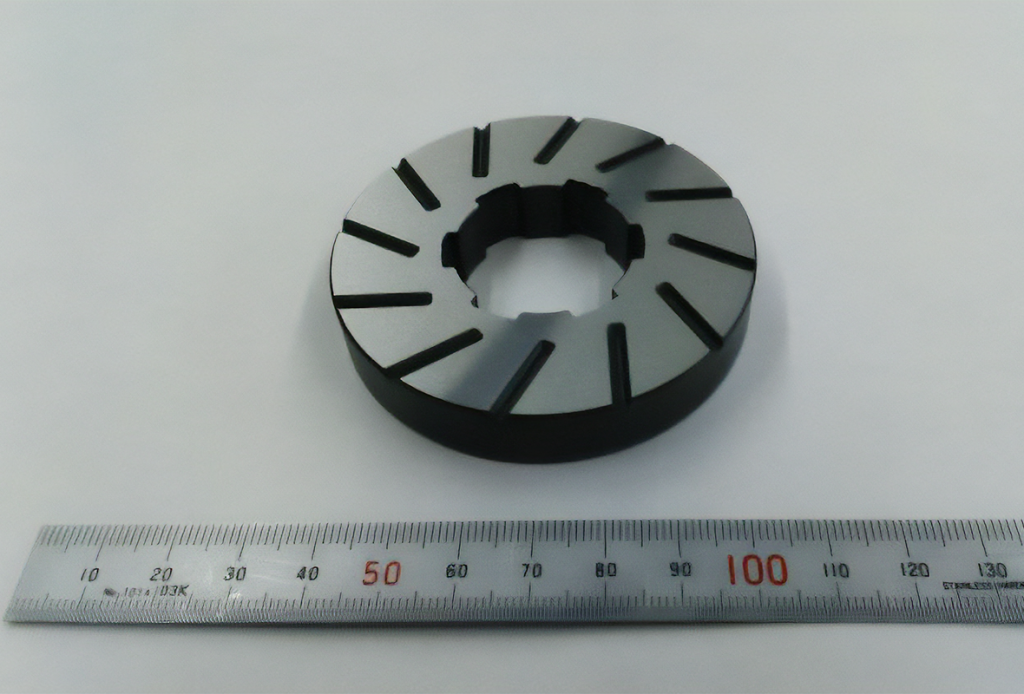

MAT21

MAT21

- sizeΦ90x8mm

- 5000 hole xΦ1x8mm

- for semiconductor

- Also available in Hastelloy

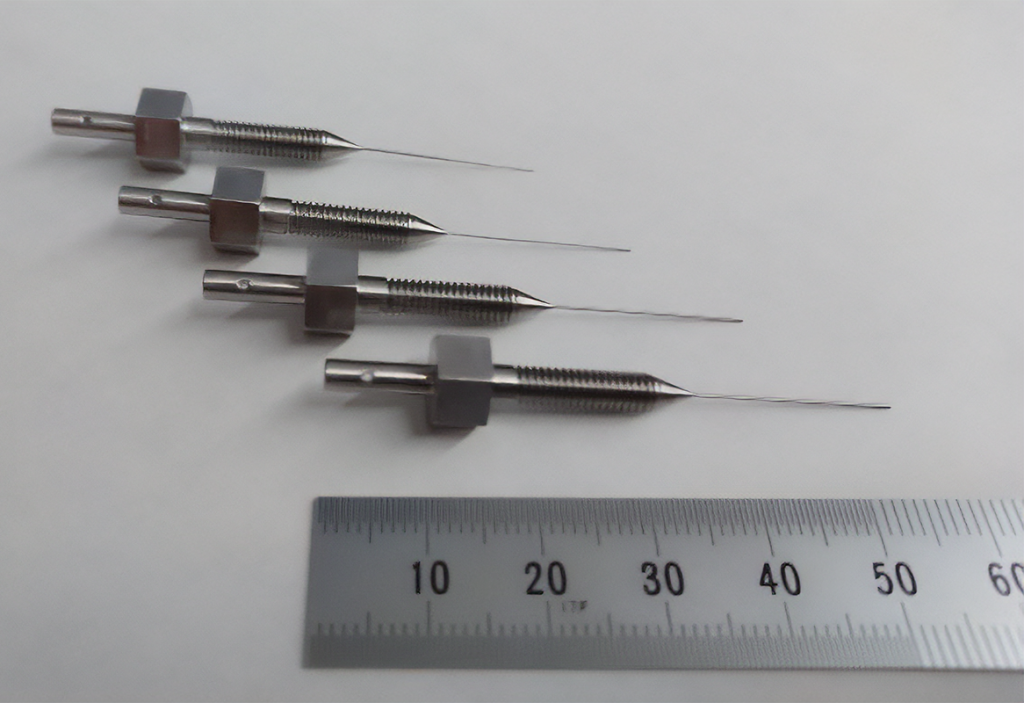

MAT21 Lathing

- Tip diameter φ0.1、φ0.2、φ0.3、φ0.4

- L=20mm

- M4 Screw φ0.7 Hole drilling

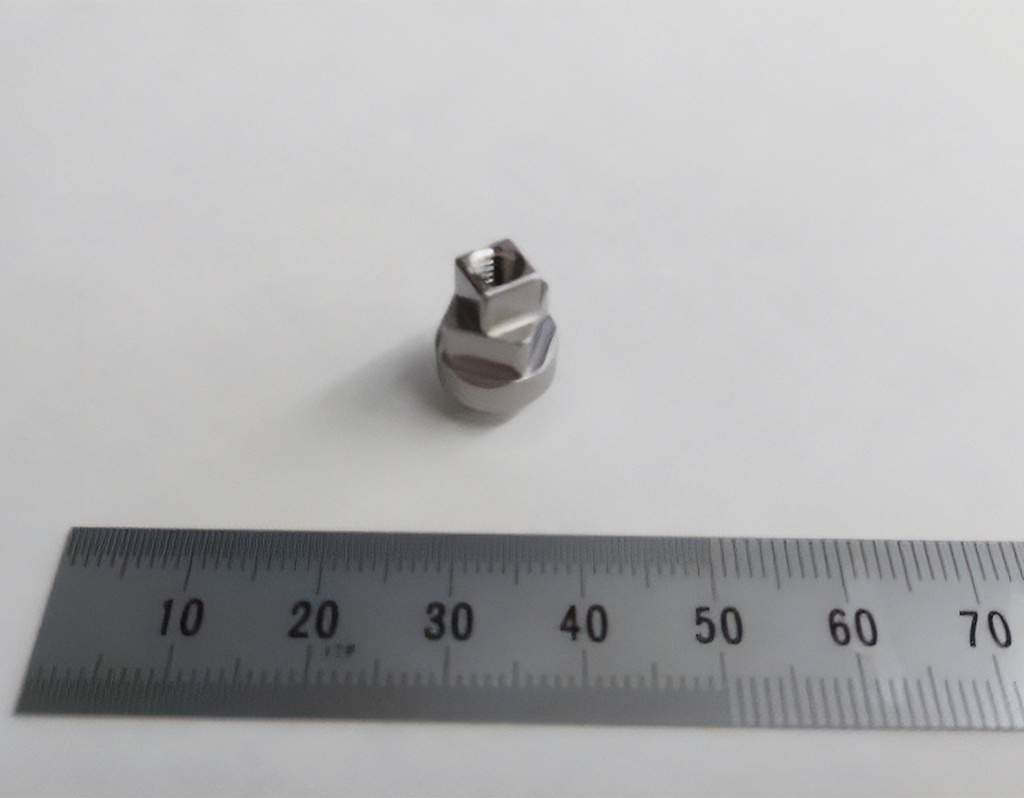

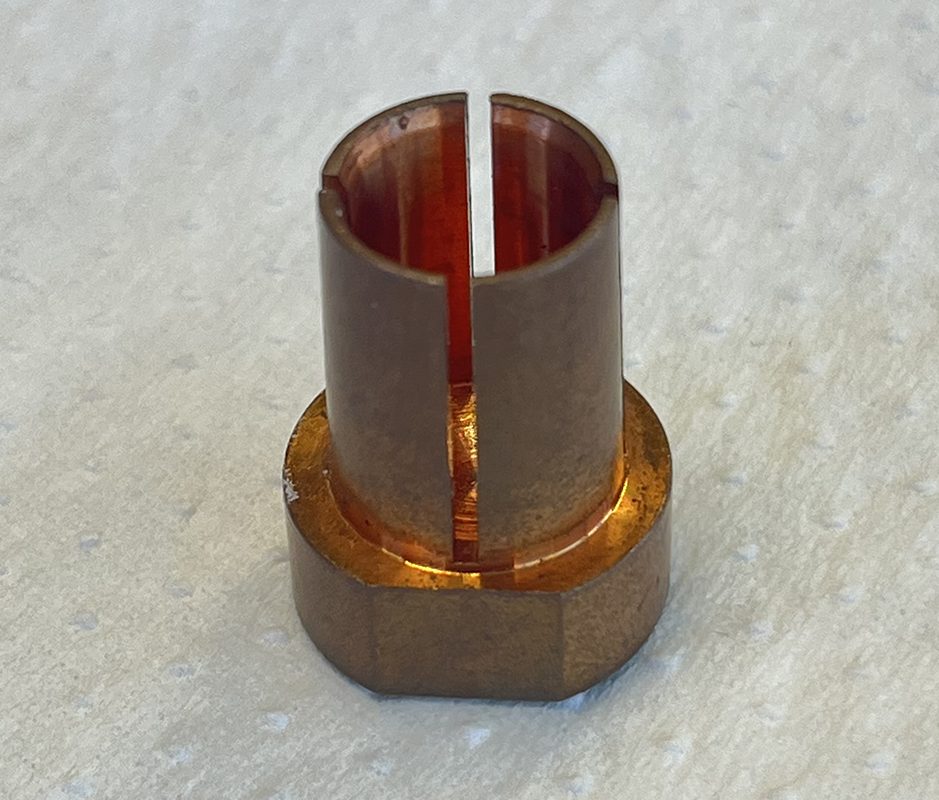

MAT21 Joint

- Joint-Cutting taper screw

MAT21

- Machining

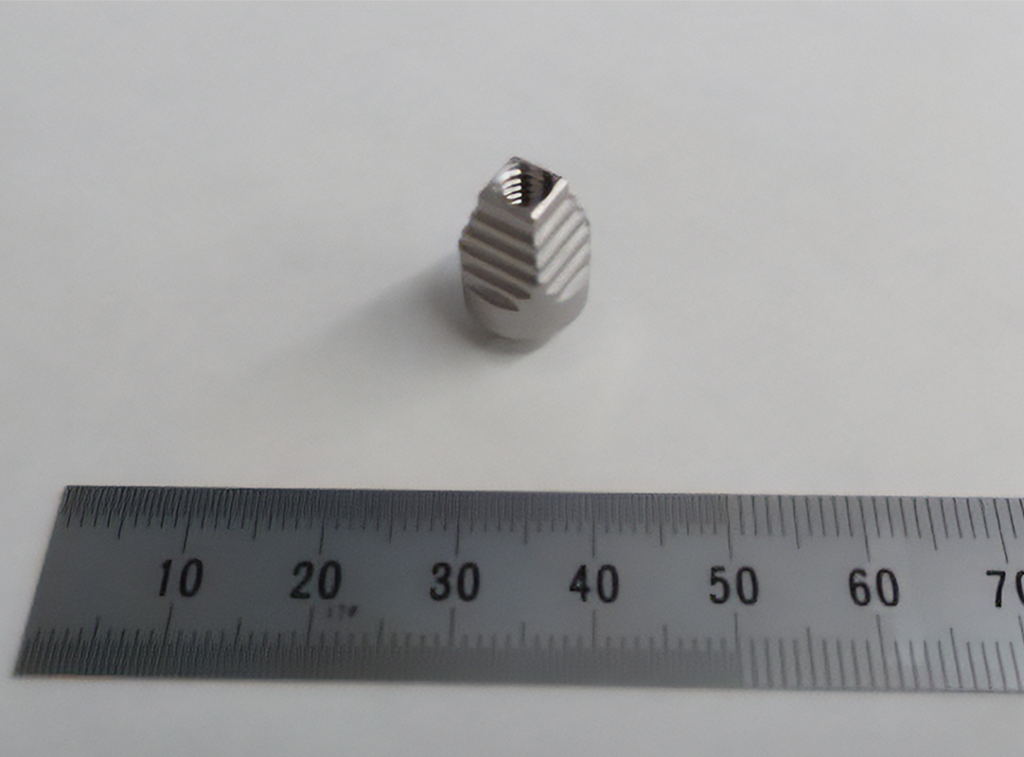

MAT21

- Machining

MAT21

- Machining

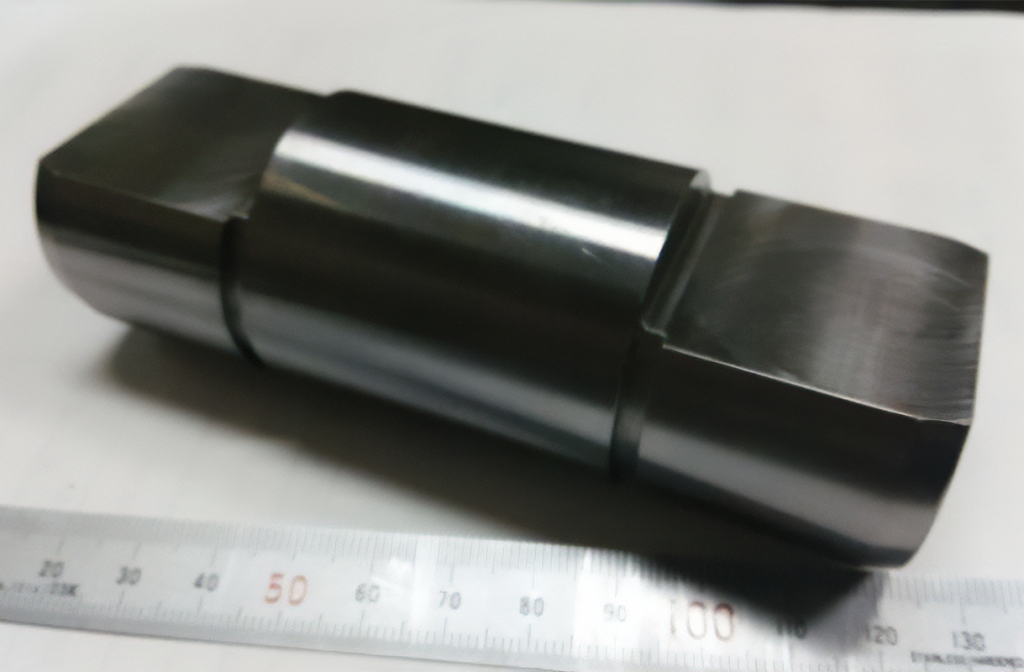

Tantalum

Tantalum

- L20mm

- Process all from φ8 with a combined lathe processing machine.

- Penetrate φ1 hole in longitudinal direction.

- Penetrate φ2 hole in transverse direction.

- M5 Outer screw. M4 Inner screw.

- D cut and groove processing.

Tantalum

- Tantalum composite processing

Niobium

Niobium

- Process all from φ12 with a combined lathe processing machine.

- Penetrate φ1 hole in longitudinal direction.

- M5 Outer screw. M4 Inner screw.

- D cut and groove processing.

Pure Nickel

Pure Nickel

- Long thing 200mm

- Outer diameter from φ4

Pure Nickel

Φ6

Pure Nickel

Φ5

Pure Nickel

- Φ5

Pure Nickel

- Φ7

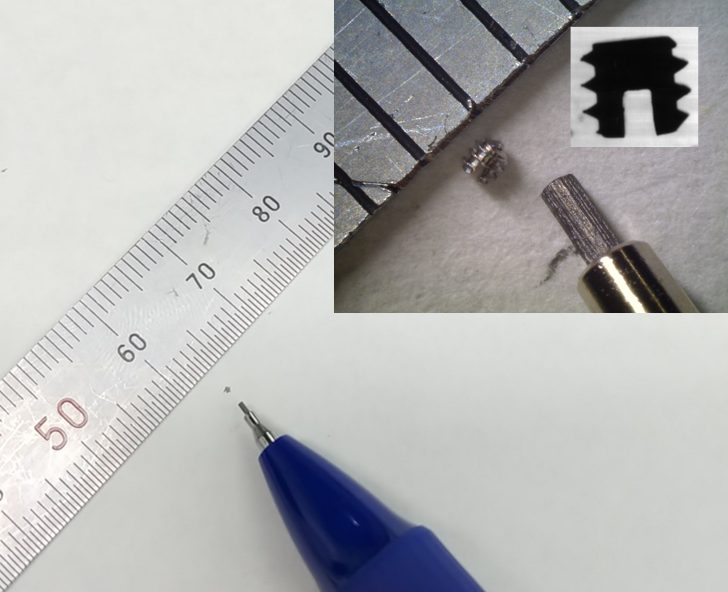

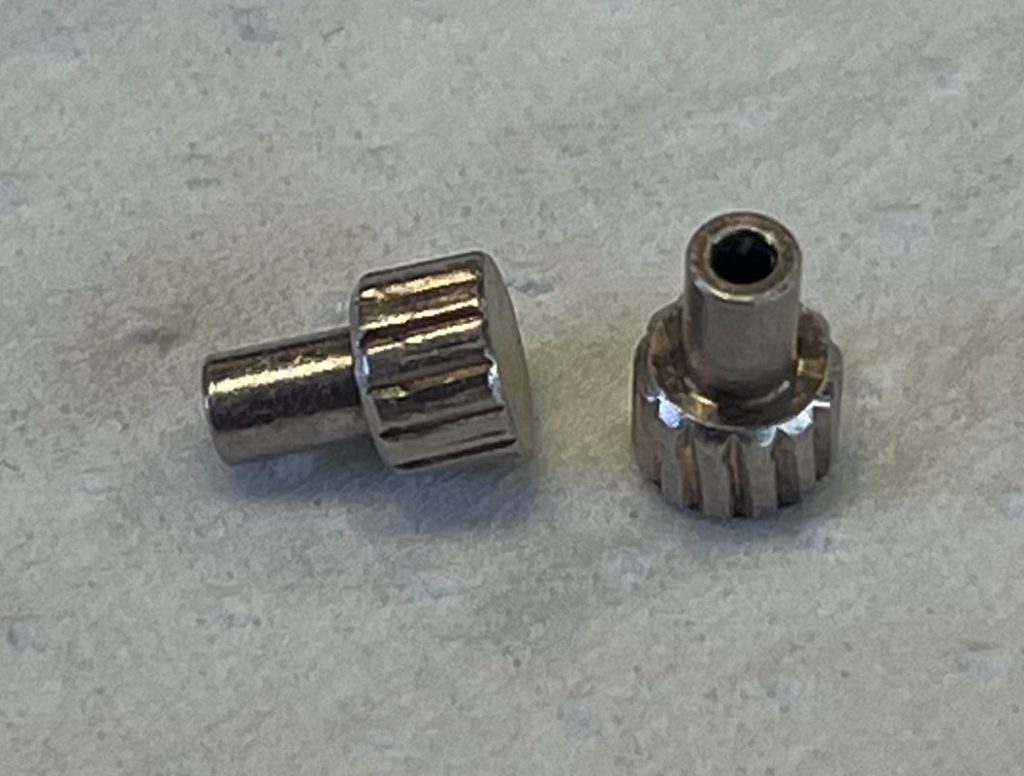

Hastelloy

M0.6ネジ加工

- ハステロイC276でのM0.6ネジ加工

- マイナスドライバー用のすり割り溝0.15mm

- SUS304から更に耐食性の強い金属への要求がありハステロイを提案して製作。

- 他にもSUS630での製作実績あり。

- 実物は肉眼では点にしか見えません。

Hastelloy φ0.2 hole processing

- Drilled φ0.2 hole in Hastelloy C276 of L20(aspect ratio 100) and L30(aspect ratio 150).

- Through 0.1mm thread.

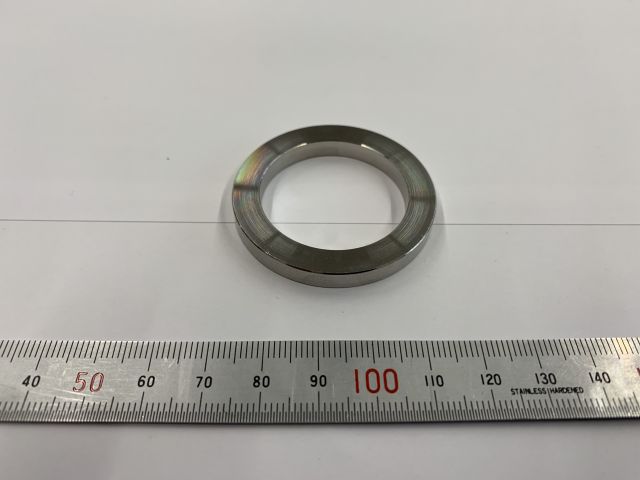

Permalloy

PB Permalloy

- PB Permalloy

- Combined processing

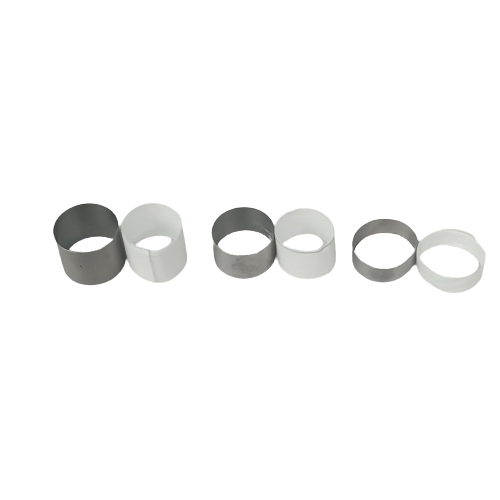

PB Permalloy

- Permalloy Ring-

PB PC Permalloy

- Left is PB Permalloy,Right is PC Permalloy.

42Alloy

42Alloy

- Microfabrication

Kovar

Kovar

- M2.5

- Screw

Kovar

- M2.6

- Tapping

Stainless

SUS303

- Inside diameter Φ6xL75mm

- Long through hole

SUS304

- with a combined lathe processing machine.

SUS316

- SUS316

- with a combined lathe processing machine.

SUS440c

- Hard turning inner diameter after heat treatment

- Inner diameter φ5×L30mm.Tolerance range ±4μ

- Surface roughness Ra0.6

SUS430

- Lathe cutting+Machining

SUS440c

- Complete heat treatment

Extra fine processing

- The left, φ0.1 L15mm

- Cutting

Extremely small hole processing

- Processing with a comb-type NC lathe.

- L28mm,18mm,14mm,14mm from left.

- Penetration of φ0.2mm hole in the middle.

鉄系・特殊鋼加工

SUJ2

- Bearing processing

SUJ2

- Outer diameter φ32.

- Hard turning after heat treatment. HRC62.

- Angle tolerance ±0.03 degrees.

- Roundness 5μ.

- Outer diameter finish is Rz0.8.

SK4

- Processing from φ32 with a combined lathe processing machine.

SUJ2

- Hard turning after heat treatment.

- Outer diameter is machined on R surface.

SACM645

- Edison hard processing

- HRC65

- Lapping after polishing

- Rmax0.3S

GOA

- Hard turning of inner diameter and end face after heat treatment.

- Surface roughness Ra0.8

Copper・Brass

C1100 Oxygen-free Copper

- width 0.8mm

- Slit processing

Brass

- Brass Products-

Deformed processing

- Process all from φ36 with a combined lathe processing machine.

Deformed processing

- With a combined lathe processing machine.

Pure Copper C1020

- Pure Copper

- with combined lathe processing machine

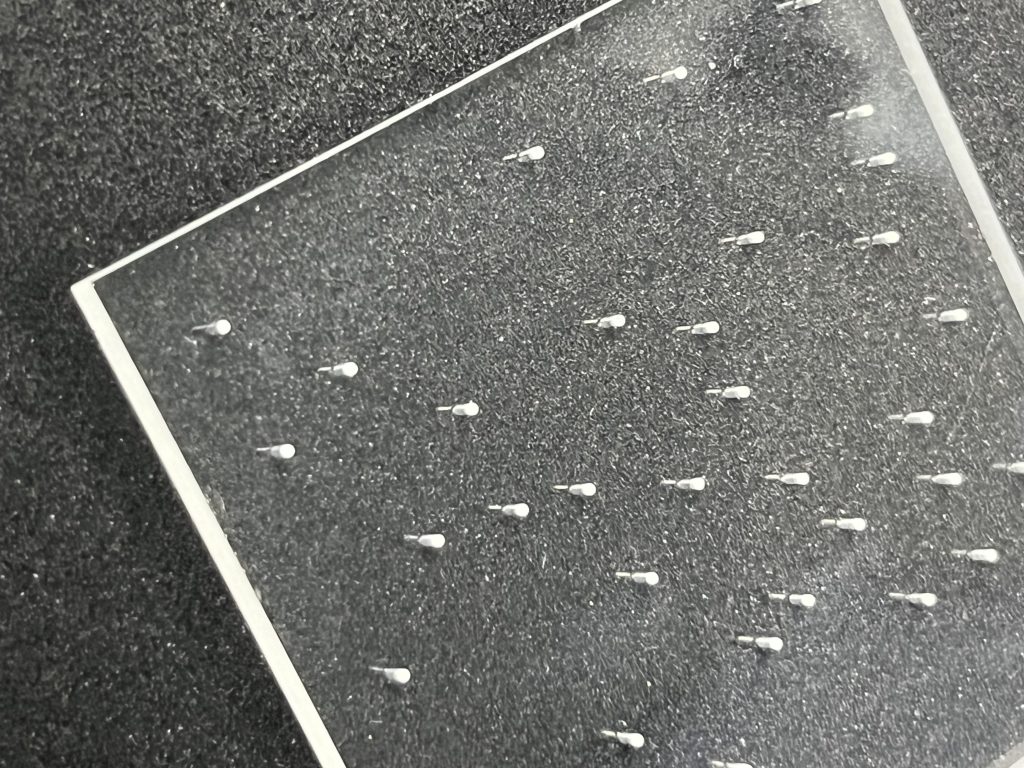

Quartz Glass

Quartz Glass

- 石英ガラスにΦ0.5穴加工

Quartz Glass

- Φ0.5穴加工(ピッチ0.5mm 厚み2mm)

Quartz Glass

- 石英ガラスの薄肉加工(厚み0.1865mm)

Quartz Glass

- Φ0.2穴加工(ピッチ0.4mm 厚み2mm)

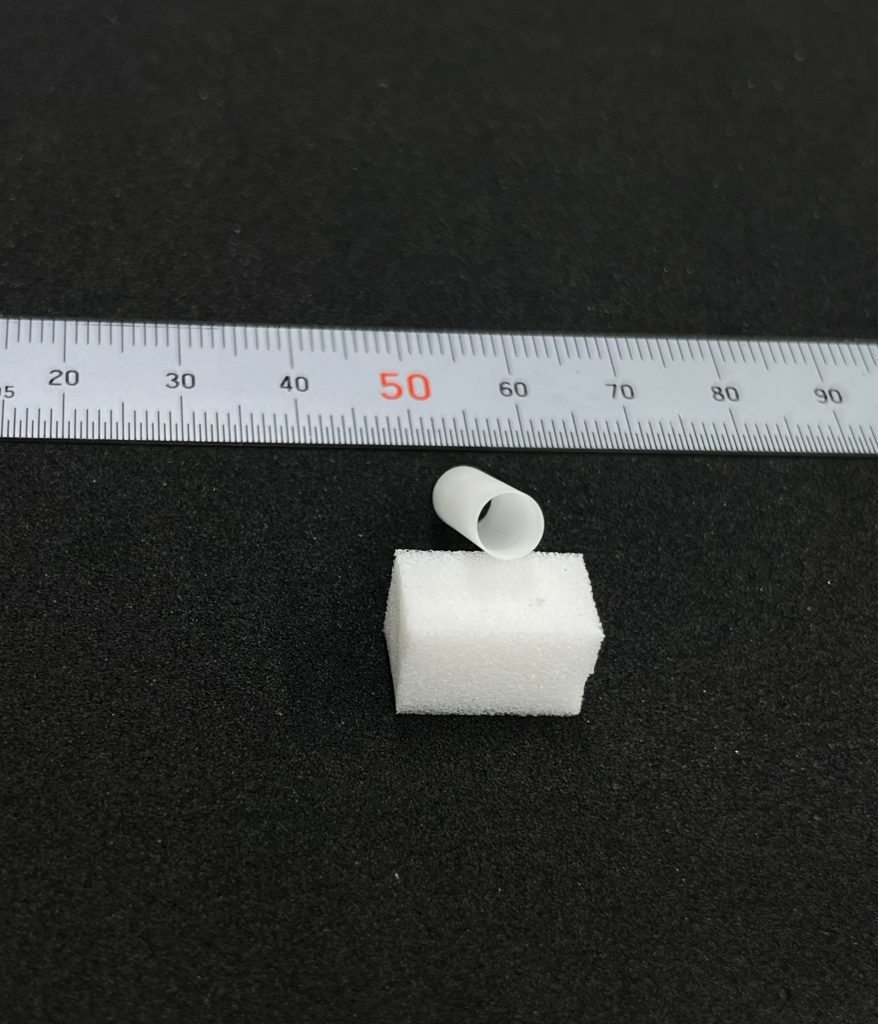

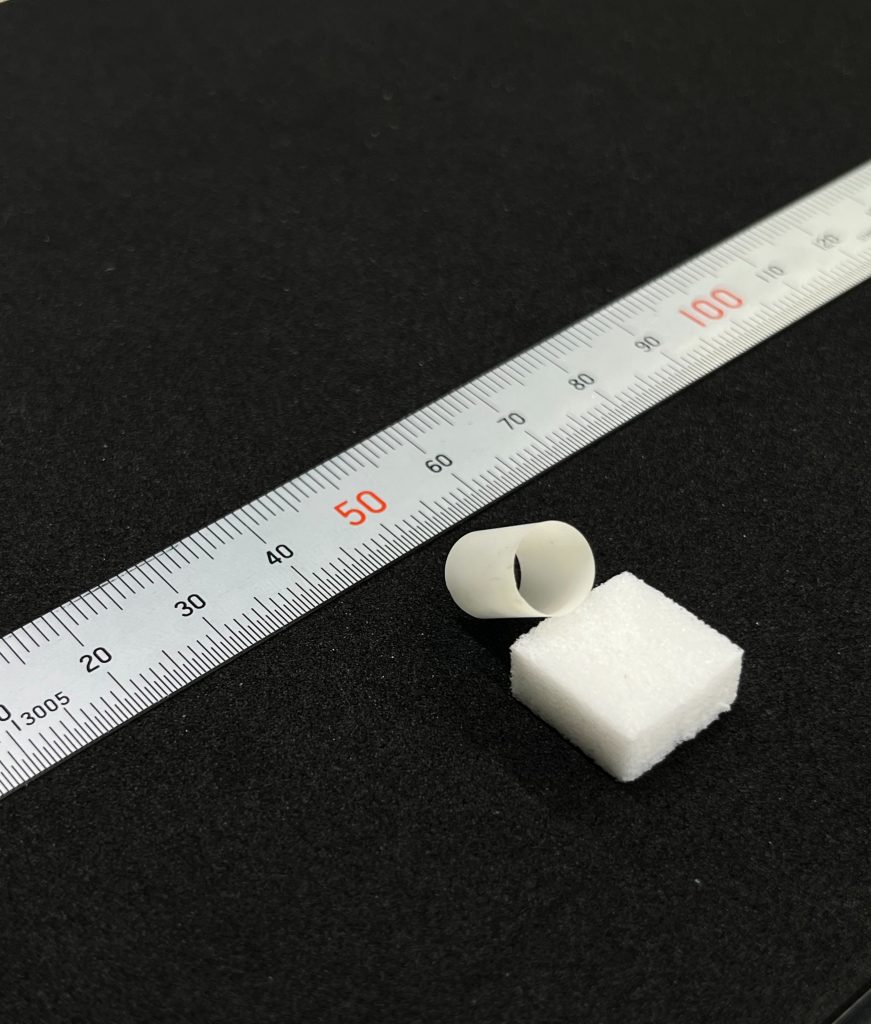

Ceramics

Ceramics

- 薄肉加工 厚み0.062

Others

Sterling silver

- Sterling silver 99.99%Ag

- Knurling

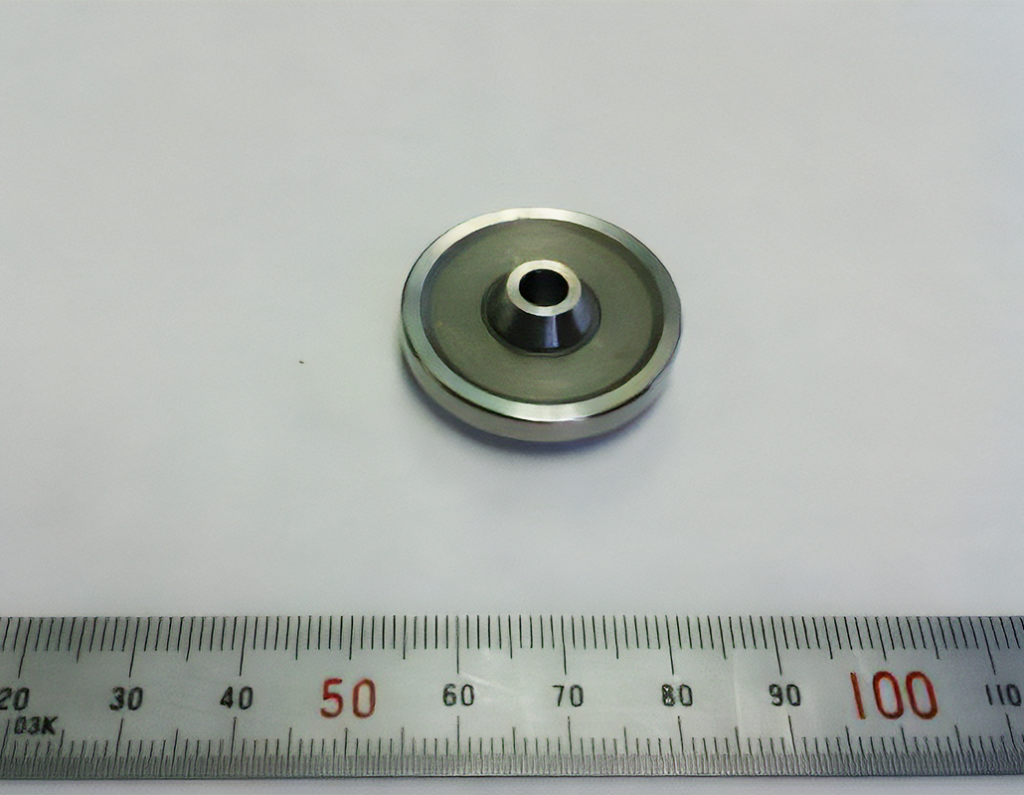

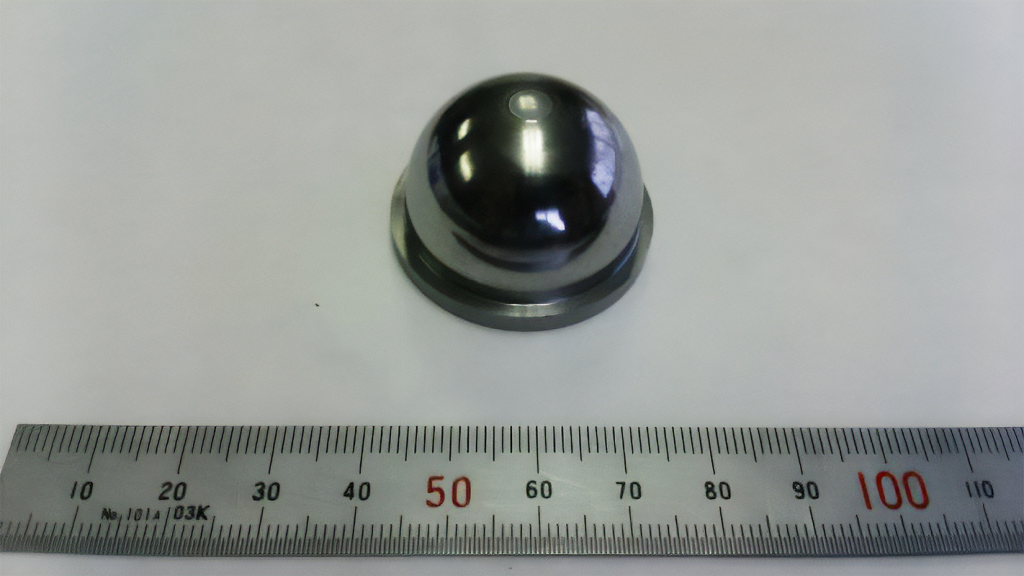

Sintering Additional machining

- Spherical procesing and Turning process to make surface roughness uniform

Aluminum deforming

- Processing from round bar by combined lathe processing

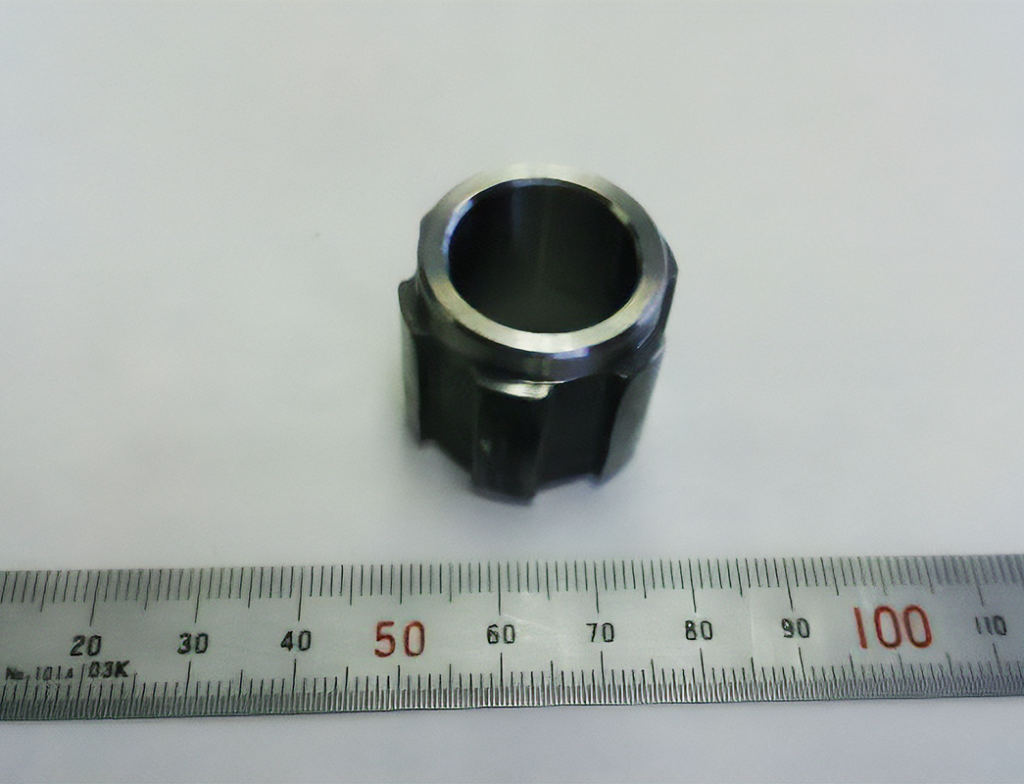

Forging Additional machining

- Additional processing of forged products.

- Inner diameter tolerance ±5μ

Microfabrication

- Inner diameter φ0.8

- Tolerance range 10μ