Permalloy: A Versatile Magnetic Alloy for Wide-Ranging Applications

Permalloy, an alloy primarily composed of nickel and iron, possesses high permeability and low coercivity, making it an indispensable material in various industries including magnetic shielding, electronic components, transformer cores, and magnetic sensors.

This article explains the characteristics, applications, and machinability of permalloy in detail.

What is Permalloy?

Permalloy is an alloy primarily composed of nickel and iron. Its unique physical and chemical properties are determined by the ratio of these components. The two types of permalloys we frequently receive machining requests for at Koyo High Precision are classified as:

- • PB Permalloy (Ni 45% – Fe 55%)

- • PC Permalloy (Ni 77% – Fe 14% – Cu 5% – Mo 4%)

Characteristics of Permalloy

High Permeability

Permalloy is a highly valued alloy in many industrial sectors due to its unique magnetic properties. Its high permeability is particularly noteworthy. Permeability is an indicator of how easily a material can be magnetized, and permalloy responds sensitively to even slight changes in external magnetic fields.

This characteristic allows it to have an excellent ability of detecting and responding to minute fluctuations in magnetic fields, thereby helping to ensure the precise operation of electronic devices.

Low Coercivity

Permalloy has low coercivity, meaning that magnetization is quickly released once the external magnetic field is removed.

Low coercivity indicates that very little residual magnetism remains after the magnetic field disappears, which is a significant advantage.

This property is particularly valuable in magnetic memory devices and sensors, where reusability and reset capability are required.

Magnetic Shielding Performance

Permalloy’s magnetic shielding performance is highly effective due to its combination of high permeability and low coercivity.

Magnetic shielding materials are used to protect equipment from unwanted magnetic fields or magnetic noise, and permalloy is extremely well-suited for this role.

Its high permeability absorbs external magnetic fields effectively, while its low coercivity helps it avoid retaining them.

As a result, it acts as a protective barrier against magnetic noise, helping maintain equipment performance.

Magnetic Flux Concentration

Permalloy exhibits magnetic flux concentration. This means it can generate significantly greater magnetization output than the input magnetic field—effectively amplifying it.

This makes permalloy ideal as a core material for magnetic sensors and power converters.

In sensors, accurate detection of subtle magnetic field changes is required, while in transformers and inductors, efficient conversion of magnetic energy is necessary.

Permalloy’s ability to concentrate magnetic flux meets these demands.

Property Enhancement through Heat Treatment

Permalloy’s properties can be further enhanced through heat treatment. Magnetic annealing at temperatures above 1000°C significantly increases permeability, resulting in improved performance for specific applications.

This treatment optimizes the microstructure of the material, enhancing its magnetic characteristics and enabling high-performance components.

Applications of Permalloy

Permalloy plays a key role in a wide range of fields—including magnetic shielding, electronic components, transformer and inductor cores, and magnetic sensors—thanks to its high permeability and low coercivity.

Magnetic Shielding

In magnetic shielding, permalloy plays a crucial role in protecting precision equipment from magnetic noise and external fields.

For example, medical devices and communication equipment that are sensitive to minor magnetic influences can lose accuracy and reliability without permalloy shielding.

Permalloy effectively blocks unwanted magnetic fields, ensuring that equipment operates under ideal conditions.

Electronic Components

Permalloy has a wide range of applications in electronic components.

In electron microscopes, it is used for magnetic shielding to prevent interference when observing microscopic samples.

In acoustic and measurement equipment, permalloy shielding cases help reduce noise and improve signal clarity.

Additionally, in inverter motor control devices, permalloy helps minimize magnetic interference, enhancing the precision and efficiency of the equipment.

Transformer and Inductor Cores

When used as cores for transformers and inductors, permalloy enables efficient power conversion due to its high permeability and magnetic flux concentration.

High permeability allows magnetic field changes to be transmitted quickly through the core, while magnetic flux concentration efficiently converts input energy to output energy.

These features allow transformers and inductors to remain high-performing while being miniaturized, improving the stability and cost-effectiveness of power supplies.

Magnetic Sensors

In magnetic sensors, permalloy enables accurate detection of small magnetic field changes, providing high sensitivity and precision in applications such as geomagnetic measurement, vehicle position and speed sensing, and digital compasses.

By using permalloy, sensors can respond quickly to subtle environmental changes and deliver reliable measurement results.

Machinability of Permalloy

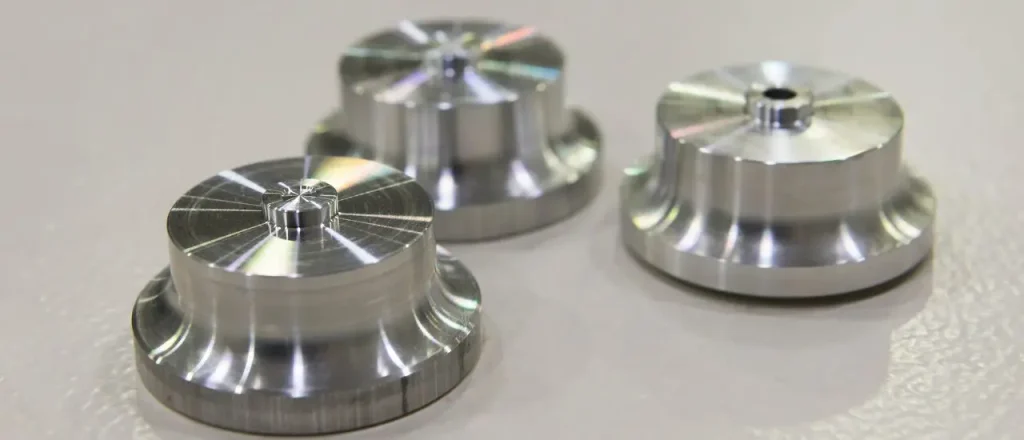

While permalloy offers good machinability among nickel-based alloys, certain characteristics make it challenging to process.

This is due to its specific viscosity, low thermal conductivity, and tendency to harden during machining.

Furthermore, permalloy tends to form strong bonds with tools during processing, and when the processed area heats up, chips or the material itself can easily adhere to the tools. Therefore, when using conventional tools, early tool wear, breakage, and decreased processing precision are likely to occur.

During processing, not only is adjusting the speed important, but also cooling the work area is critical. Proper cooling depends on selecting and supplying the right cutting oil, which plays several key roles beyond cooling—such as reducing tool wear and helping with chip evacuation.

Therefore, high-precision machining of permalloy requires specialized knowledge and techniques, including the selection of appropriate tools and the setting of optimal cutting conditions.

Trust Koyo High Precision for Machining Materials

At Koyo High Precision, we combine cutting-edge technology with years of hands-on experience to expertly handle the machining of even the most difficult-to-cut materials.

No matter how challenging the material, we can identify the perfect machining conditions by carefully monitoring chip formation, tool wear, cutting surface quality, and even the sounds during machining.

We are committed to providing customized solutions that meet your unique needs. Contact us today for consultations or quotations — we’re here to help with all your difficult-to-machine material requirements.