Permendur: A Soft Magnetic Material with Superior Magnetic Properties

Permendur, an alloy composed of 50% iron and 50% cobalt, is renowned for its exceptional magnetic properties, outperforming other soft magnetic materials.

With its high saturation magnetic flux density, Permendur is widely used in the electrical and electronic engineering industries.

This article explores the characteristics, advantages, challenges, and varied applications of Permendur.

What is Permendur?

Permendur is a soft magnetic material composed of 50% iron (Fe) and 50% cobalt (Co), famous for its superior magnetic properties. The name is derived from the scientist who discovered this material.

Thanks to its high saturation magnetic flux density and excellent magnetic properties, Permendur is widely used in electrical and electronic engineering applications.

Characteristics and Advantages of Permendur

The primary advantage of Permendur lies in its high saturation magnetic flux density. This property is particularly exceptional among soft magnetic materials and plays a crucial role in products such as solenoid valves, electromagnets, motors, and speakers.

Permendur’s capabilities are especially valuable in the development of next-generation, energy-efficient motors. Its superior magnetic properties greatly contribute to enhancing product performance.

Challenges with Permendur

While Permendur alloy is highly regarded for its magnetic properties, surpassing other materials like Permalloy and Sendust—especially in terms of high saturation magnetic flux density—there are some challenges associated with its production and use.

The materials required for manufacturing Permendur often include cobalt (Co) and vanadium (V), which are subject to price volatility and supply instability. These elements are concentrated in specific regions, making their prices and supply vulnerable to political issues and fluctuations in mining output.

As a result, the cost of Permendur alloy is heavily influenced by raw material market fluctuations, which can impact product prices.

Applications of Permendur

Leveraging its high magnetic flux density, Permendur helps with product miniaturization while boosting performance. It’s widely used in a variety of applications, including electromagnets, motors, solenoid valves, and magnetic lenses.

Electromagnets

In the world of electromagnets, the use of Permendur greatly enhances the ability to generate powerful and efficient magnetic fields. Permendur achieves magnetic field strengths and control that were once difficult to attain with conventional materials.

This advantage helps dramatically improve the functionality of precision machinery, medical devices, and various everyday products.

Motors

In the motor industry, the introduction of Permendur enables the manufacture of compact, high-output devices. Energy efficiency is especially important in products requiring energy conservation, such as electric vehicles and drones, significantly affecting product competitiveness.

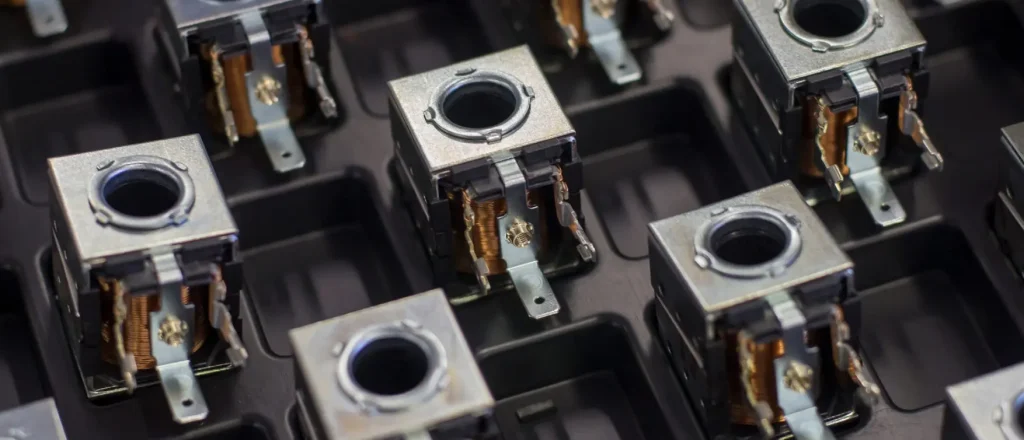

Solenoid Valves

Solenoid valves play a central role in fluid control. In scenarios requiring precise control and rapid response, Permendur’s properties offer significant advantages.

For example, fluid management systems in automobiles and household appliances gain efficiency and reliability from this high-performance material.

Machinability of Permendur

Permendur presents significant challenges when it comes to machinability. The alloy is quite brittle during processing, making cold working especially difficult.

To overcome this, vanadium is often added as a solution. A common alloy composition that improves machinability includes 49% iron, 49% cobalt, and 2% vanadium.

However, even with vanadium added, the material’s brittleness isn’t entirely removed. As a result, it’s important to be prepared for potential issues like cracking or chipping during processing.

Trust Koyo High Precision for Machining Difficult-to-Cut Materials

At Koyo High Precision, we combine cutting-edge technology with years of hands-on experience to expertly handle the machining of even the most difficult-to-cut materials.

No matter how challenging the material, we can identify the perfect machining conditions by carefully monitoring chip formation, tool wear, cutting surface quality, and even the sounds during machining.

We are committed to providing customized solutions that meet your unique needs. Contact us today for consultations or quotations — we’re here to help with all your difficult-to-machine material requirements.